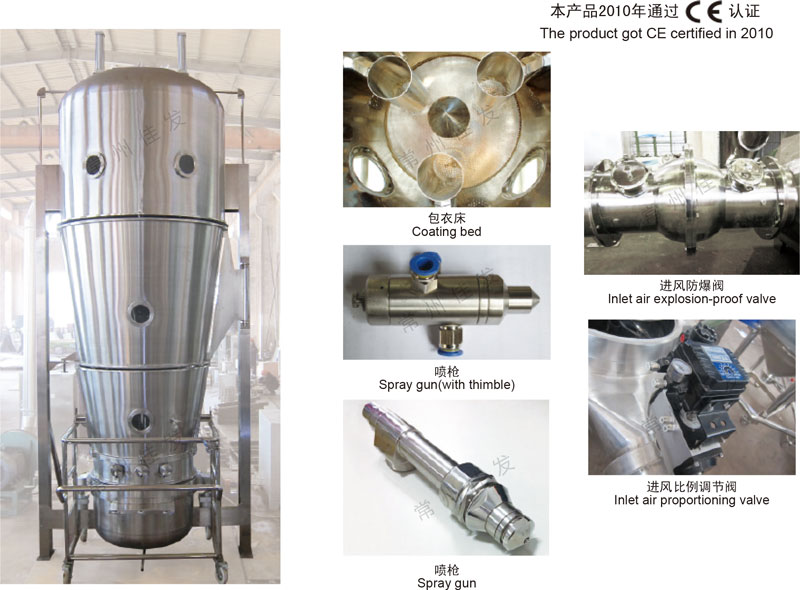

Application Overview

Fluidized bed coating machine is a new type of particle coating equipment that organically combines fluidization coating technology and spray technology. It is widely used for film slow and controlled release, skeleton slow and controlled release capsules, pill coating, particle and powder coating.

Equipment characteristics

★Bottom jet fluidization allows the material to have a certain regular operating trajectory, thus obtaining a uniform and continuous coating film.

★Powder, particle, pill masking, moisture-proof, oxidation resistant, waterproof, heat resistant, coloring isolation and other coatings.

★No loss of coating materials and low production costs.

★The route of fog particles to materials is short, so there is no danger of "spray drying".

★The cylindrical acceleration container or inverted cone deceleration design can be used for coating particles, large particles, small particles, and pellets.

★The material has excellent dispersibility and no adhesion.

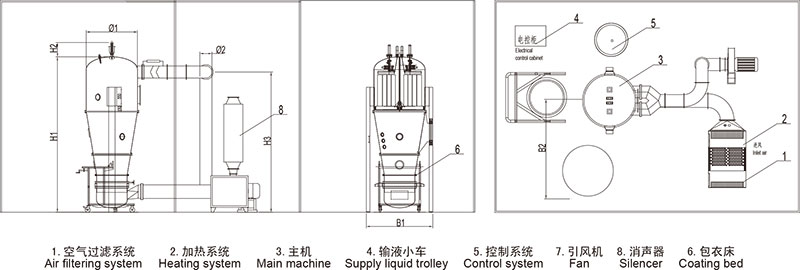

Outline Dimensional Drawing

Project specifications | 5 | 15 | 30 | 60 | 120 | 200 | 300-800 | ||

Inventory | kg/batch | 4-6 | 10-20 | 25-40 | 40-80 | 80-150 | 150-250 | Design according to user requirements | |

Raw material container capacity | L | 15 | 50 | 100 | 220 | 360 | 650 | ||

Fan power | Kw | 4 | 5.5 | 7.5 | 15 | 18.5 | 22 | ||

Compressed air | Pressure | Mpa | 0.6 | ||||||

Consumption | m3/min | 0.4 | 0.6 | 0.9 | 1.3 | 1.8 | 2.4 | ||

Steam | Pressure | Mpa | 0.4-0.6 | ||||||

Consumption | Kg/h | 9KW | 64 | 85 | 181 | 250 | 330 | ||

Host size | H1(mm) | 2600 | 2850 | 3150 | 3250 | 3500 | 3800 | ||

H2(mm) |

| 340 | 490 | 590 | 790 | 890 | |||

H3(mm) |

| 2630 | 2930 | 3020 | 3280 | 3580 | |||

B1(mm) | 1010 | 1160 | 1460 | 1660 | 2060 | 2260 | |||

B2(mm) | 1560 | 1860 | 2460 | 2860 | 3660 | 4060 | |||

?1(mm) | 550 | 700 | 1000 | 1200 | 1600 | 1800 | |||

?2(mm) | 180 | 250 | 250 | 280 | 280 | 315 | |||

L(mm) | 850 | 1550 | 1700 | 1800 | 2000 | 2100 | |||

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.