Application Overview

The high-efficiency non porous coating machine is used in the pharmaceutical and food industries for sugar coating, organic film coating, water-soluble film coating, sustained-release, and controlled release coating of tablets, pills, pellets, water pellets, drops, and granules. It is particularly suitable for Chinese and Western medicine tablets and meets GMP requirements.

Equipment characteristics

★It has all the characteristics of the BGB series efficient coating machine.

★Computer control, touch screen display.

★The coating drum is of a non porous structure, with low energy consumption and wide applications.

★It is possible to coat the core with a diameter of 0.6mm or more.

★Organic film coating, water-soluble film coating, sustained-release coating, and controlled-release coating.

★The inlet and exhaust ducts can be interchanged as needed.

★The wind propeller can be embedded or removed from the material according to the process requirements.

★Equipped with a special cleaning and elimination device.

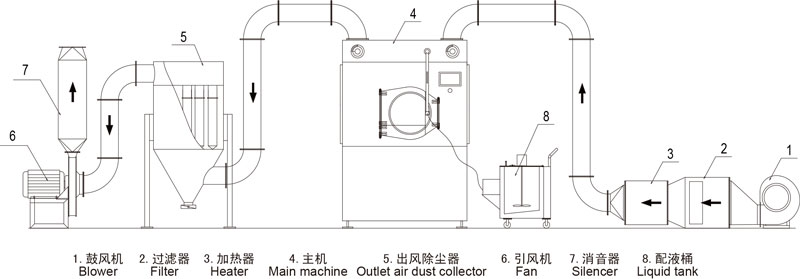

Technological process

Project specifications | BGW10 type | BGW40 type | BGW80 type | BGW150 type | |

Production capacity (Kg/batch) | 10 | 40 | 80 | 150 | |

Drum speed (rpm) (rpm) | 6-25 | 5-22 | 4-19 | 3-15 | |

Host power(Kw) | 0.55 | 0.75 | 1.5 | 2.2 | |

Host volume(L×W×H) (mm) | 900×1170×1320 | 1000×1380×1540 | 1210×1800×1850 | 1450×2100×2100 | |

Coating drum diameter (mm) | ?600 | ?825 | ?1006 | ?1280 | |

Exhaust cabinet motor power (Kw) | 0.75 | 2.2 | 3 | 5.5 | |

Motor power of hot air cabinet (Kw) | 0.55 | 0.75 | 1.1 | 1.5 | |

Diameter of feeding port (mm) | 260 | 340 | 380 | 458 | |

Air volume (m3/h) | <700 | <2000 | <3600 | <4500 | |

Weight (Kg) | 450 | 550 | 800 | 1000 | |

External dimensions of the hot air cabinet(L×W×H) (mm) | 850×650×1950 | 900×800×1500 | 1000×900×1650 | 900×1000×1650 | |

External dimensions of exhaust cabinet (L×W×H) (mm) | 850×650×1950 | 820×720×1750 | 900×820×1850 | 950×950×1950 | |

Clean compressed air | Pressure(Mpa) | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 |

Gas consumption(m3/min) | 0.2 | 0.2 | 0.35 | 1.5 | |

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.